Applications

Nowadays, edge devices monitor a range of inputs, via sensors, and alter a set of outputs, via actuators, based upon the status of the inputs. Sophisticated low-power design and processing at the edge will allow even more computing to be done at the edge, instead of in the cloud.

Using TiF-MEMRiSTORs the development of resource-efficient edge devices with implemented real-time, noise-robust, and adaptive data processing will become child’s play.

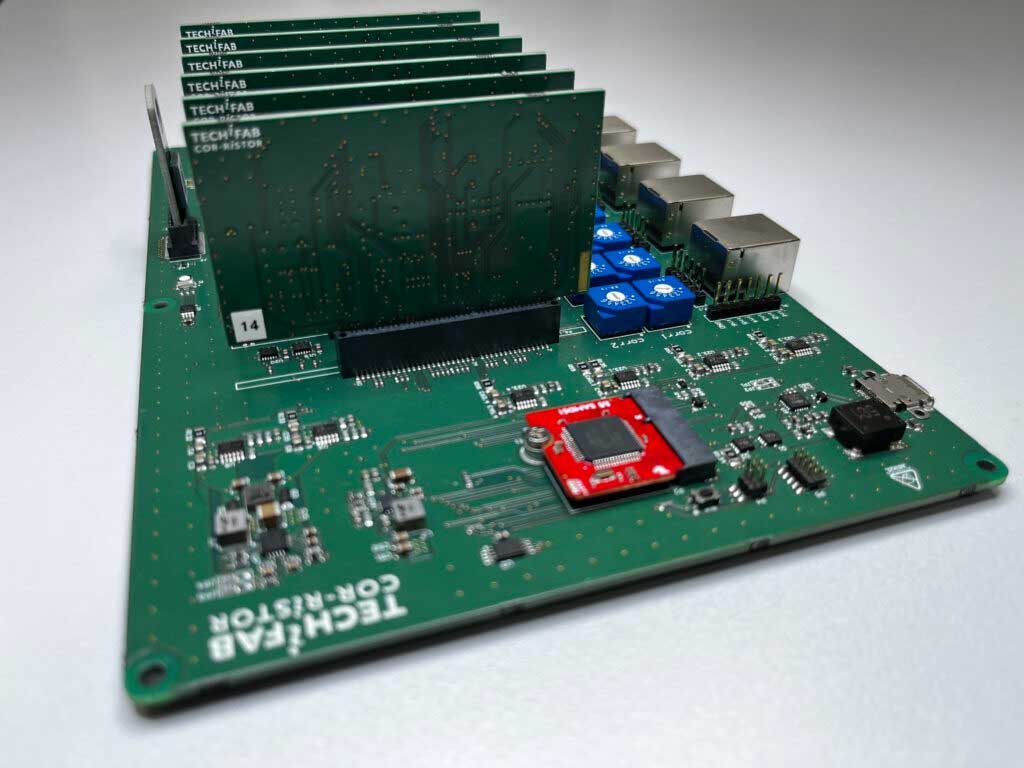

COR-RiSTOR

TECHiFAB has developed a first demonstrator device with TiF-MEMRiSTORs to connect with edge sensors to improve predictive maintenance and infrastructure monitoring: the COR–RiSTOR. With COR-RiSTOR you can experience the power of TiF-MEMRiSTORs by unveiling correlations that were previously unseen.

Applications build on top of COR-RiSTOR can become a crucial building block for Industry 5.0 and next-level data mining, thanks to the enormous potential for high-precision data analysis accompanied by energy savings and real-time sensor monitoring.

How the COR-RiSTOR changes the game

INNOVATIVE

Exploit pairwise correlations between sensor inputs.

SECURE

Store and process more sensor data at the edge, identify falsy data on-the-fly and save time and energy spent on data transmission.

RESOURCE-SAVING

Avoid computional intensive regression analysis.

Drive new ICT products with TiF MEMRiSTORs and develop your own ICT product for predictive maintenance and infrastructure monitoring- fully deterministic and transparent.

COR-RiSTOR SaaS

CORRiSTOR SaaS to analyze pairwise correlations between your input data

COR-RiSTOR Demonstrator

Demonstrator to compute significant pairwise correlations of input sensor data at the edge and to determine corresponding state of the system in real-time.

COR-RiSTOR support service

Support service to further develop COR-RiSTOR demonstrator into your new ICT product for predictive maintenance and infrastructure monitoring

Any Questions? For more information contact sales

or visit our COR-RiSTOR kickstarter page

Advantage in Predictive Maintenance

Predictive maintenance systems require real-time data from the plant, machinery, and infrastructure systems. This data comes from external or internal sensors and is combined with data from the machine control and infrastructure monitoring. This is because the latter contain the processing program and therefore the “normal values” or target values. The sensors, on the other hand, supply actual values. In the beginning, the actual values and target values of each individual sensor were considered separately for the comparison between actual values and target values. This resulted in incorrect decisions if the sensor data was incorrect.

Nowadays, an algorithm that is trained in neural networks is used as standard to compare actual values and target values. A trained neural network considers all sensor data in its entirety and immediately recognizes faulty sensor data. The hardware for neural networks is also already optimized so that it can find solutions for the algorithm in real time after training on the sensor.

However, the solutions of the neural networks for the decision-making process are usually a black box, as the logical steps that led to the solution of the trained neural network are often unknown. Fully automated use of machine control and infrastructure monitoring requires comprehensible solutions from the algorithm to compare actual values and target values.

TECHiFAB has developed an algorithm – the COR-RiSTOR algorithm – for comparing actual values and target values, in which the logical steps of the solution are comprehensible. The COR-RiSTOR algorithm considers all sensor data in their entirety as well as all sensor data in pairs. After training, the physical correlations of all sensor data are determined in pairs. The hardware for calculating the physical correlations of the sensor data on the sensor in real time – the TiF-MEMRiSTOR – is an analog, error-resistant component. The TiF-MEMRiSTOR was developed by TECHiFAB as a stand-alone component and is being used for the first time in an ICT product in the COR-RiSTOR demonstrator. TECHiFAB offers support for equipping existing sensor units in the field of predictive maintenance and infrastructure monitoring with COR-RiSTOR modules, which are connected directly downstream of the sensors.

The COR-RiSTOR algorithm can also only deliver meaningful results if it has been provided with extensive training data in advance. The sensor data must also be prepared before training and subsequent operation so that the COR-RiSTOR algorithm can process it. As a result of training with the COR-RiSTOR algorithm, the state of the system is determined from the totality of all sensor data and the physical correlations of all sensor data in pairs in a logically comprehensible manner. Atypical changes in sensor data are also recognized and at least corrected before being used to determine the state of the system.

A continuous data stream poses much less of a challenge for the COR-RiSTOR algorithm than for trained neural networks. Gradual changes in the state of the system can be detected in real time with the COR-RiSTOR algorithm if the TiF-MEMRiSTOR is used in the COR-RiSTOR modules, which are connected directly downstream of the sensors, to calculate the physical correlations of all sensor data pairwise at the sensor.

Predictive maintenance and infrastructure monitoring is a topic that industrial companies will no longer be able to avoid in the medium term.

Use the COR-RiSTOR to increase the financial benefits of your predictive maintenance and infrastructure monitoring solutions.